crusher jaw

.jpg)

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

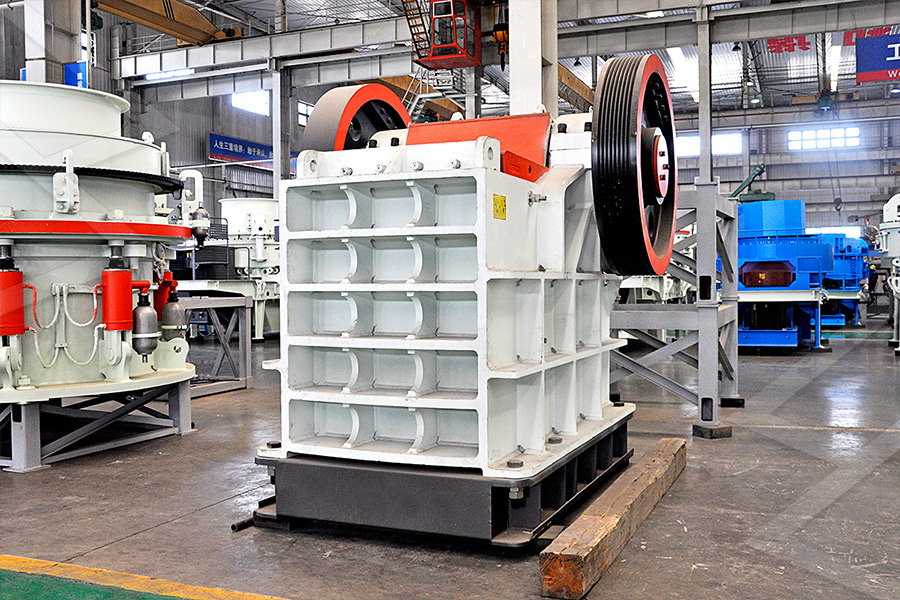

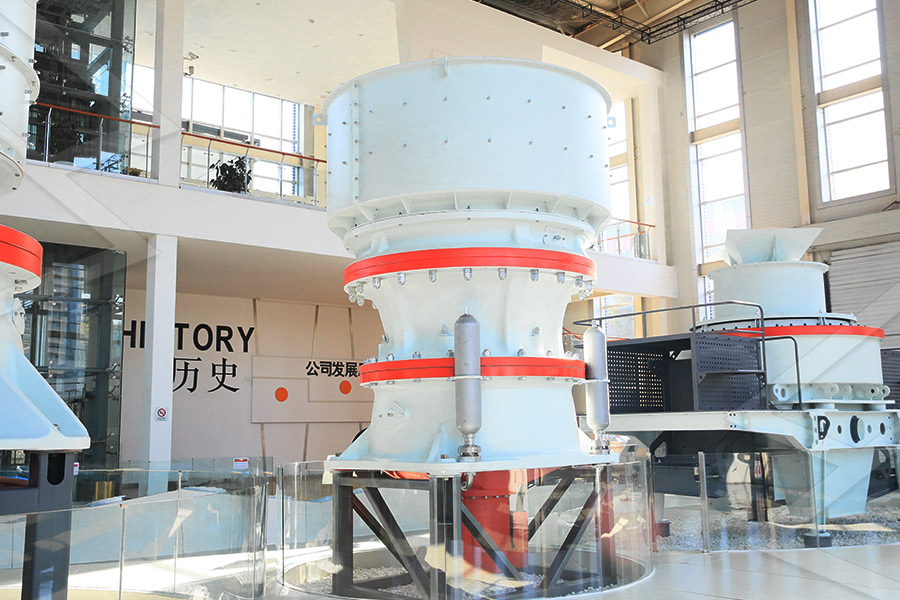

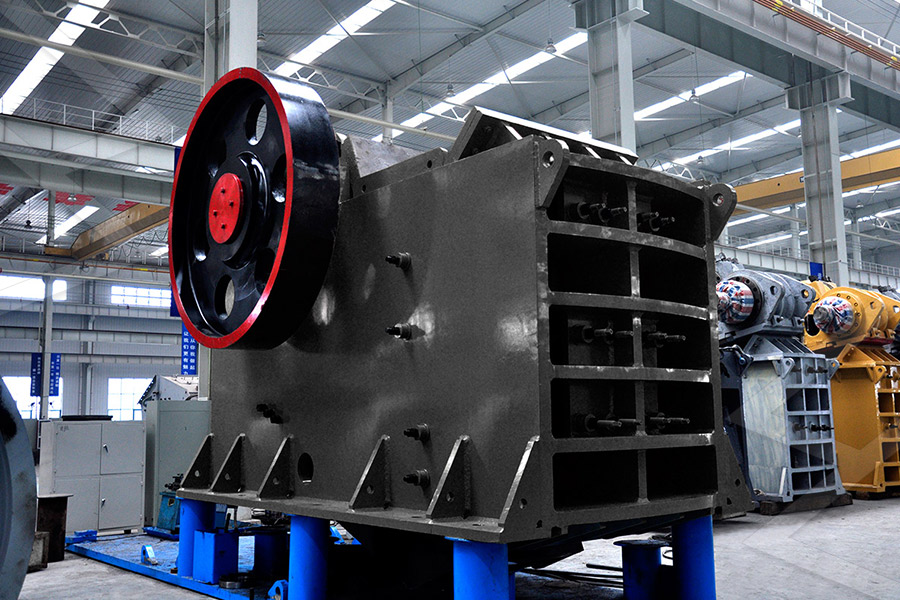

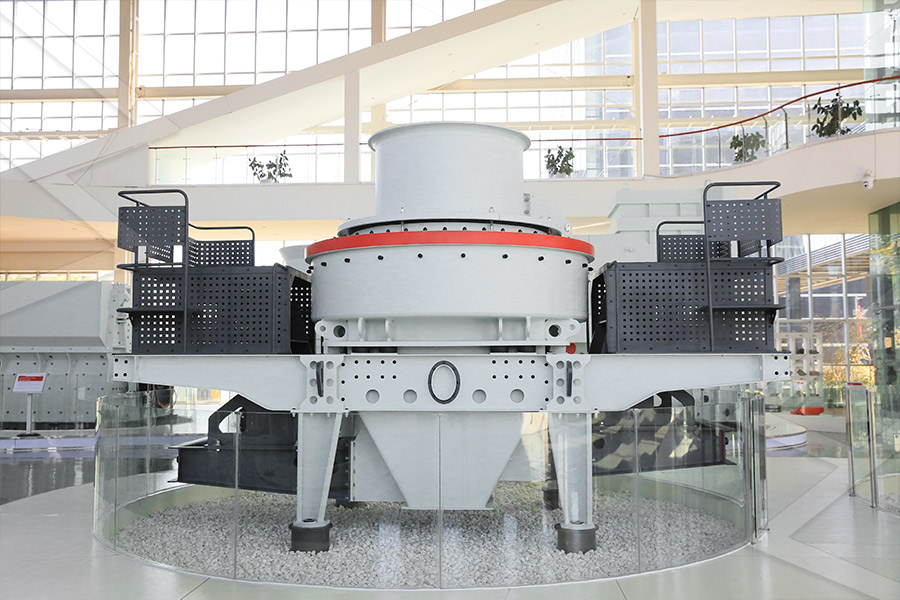

The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for online quality control of raw materials The The RETSCH jaw crusher series is available in 8 different sizes Throughput 创建PDFIt is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is under 200Mpa, that is, suitable for primary crush jaw crusher 百度百科山特维克 CJ409 颚式破碎机采用重型设计,具有出色的可靠性和稳定性,广泛适用于各种严苛条件下的应用。 Products Lifecycle services Sustainability News Media CJ409 颚式破碎机

颚式破碎机 实验室破碎机 金木石实验室科技

金木石科技的DJ和DJC系列实验室颚式破碎机具备结构简单、操作方便、耐磨性能优越等特点,能够轻松应对各种硬度的固体物质,可用于实验室大批量或连续作业,可满足分析 2024年8月29日 — The C5X Jaw Crusher boasts superior motion characteristics and crushing chamber, featuring a larger stroke and higher speeds that significantly enhance crushing C5X Jaw Crusher Industrial Technology Group3 天之前 — Compared with traditional jaw crusher, JC series jaw crushers pays more attention on details in the process of design and manufacture It uses highstrength materials, advanced manufacturing technology, which Jaw Crusher, Jaw Crusher price, jaw crusher All jaw crushers feature two jaws: one of which is fixed while the other moves The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or WHAT IS A JAW CRUSHER? MEKA

.jpg)

Sandvik QJ341 Mobile Jaw Crusher – World

Sandvik QJ341 mobile jaw crusher features a 1,200 x 750mm (47 x 29 in) jaw opening, built to tackle the most difficult applications with ease It has been designed to meet the needs of the operator seeking a high Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement There are also primary Jaw Crushers – MEKAI bought a 10″ x 16″ jaw crusher from Mt Baker Mining in February 2014 for crushing concrete and demolition debris I have installed a 37 hp gasoline motor on the crusher so it is mobile and I can haul it on the back of my Jaw Crushers Mt Baker Mining and Metals2021年5月6日 — The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw The crusher discharge opening governs the size of Jaw Crusher Working Principle 911 Metallurgist

Jaw Crusher an overview ScienceDirect Topics

Crushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be The powerful jaw crusher is capable of a variety of tasks with its large underbelt clearances, and is equipped with a hydraulic raise and lower facility on the main conveyor as standard There are a number of features to minimize operator intervention whilst maximizing their safety, such as the selflocking hopper and jaw level sensor which Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher CRUNCHY COMPACT MiniJaw Crusher Crunchy compact Crunchy’s main features are the low noise level and the singlephase power supply with low electrical absorption (only 22 kW)Furthermore, the machine is sturdy, light and equipped with wheels so Crunchy Compact Jaws Mini Crushers2024年7月15日 — A jaw crusher can be sectionalized, therefore it is advantageous to install jaw crusher in remote locations, underground Jaw crusher machine installation cost is relatively higher than gyratory crusher while its investment and maintenance cost is much lower than that of gyratory crusher Jaw crusher and gyratory crusher process granite What Are the Differences Between The 7 Types of Crushers?

.jpg)

jaw crusher 百度百科

Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is under2024年2月18日 — A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals Comprising type of jaw crusher—the robust Singletoggle and the efficient Doubletoggle—these hefty machines operate on the principle of compressing materials between Jaw Crusher Diagram: Simplified Guide JXSC2024年2月5日 — A jaw crusher operates by the movement of a movable jaw in relation to a fixed one to crush large rocks into smaller pieces It does this by using a spinning shaft that makes the movable jaw move back and forth When the movable jaw goes towards the fixed jaw, it squishes the stuff in between and breaks it into smaller bits How Does a Jaw Crusher Work? A Simple Guide JXSCThe core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse especially for jaw crushers In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that ® C Series™ jaw crushers

Types of Crushers Explained: Everything You

2024年4月19日 — There are two main types of jaw crushers: simpletoggle and doubletoggle A singletoggle jaw crusher is simpler in design and is widely used because of its low cost and ease of maintenance On the 1 天前 — Jaw Crushers Designed to crush ROM feed material for demanding quarrying, mining, and demolition purposes With their unique Elliptical motion of the swing jaw Crushers, ensure highly efficient production Jaw Crushers Manufacturer in India Puzzolana2023年2月16日 — For example, in a typical jaw crusher, the length of the jaw plate may range from around 24 to 36 inches, and the width may range from around 12 to 16 inches The thickness of the jaw plate may vary from Jaw Plates: Everything You Should KnowThis is because the Blake Jaw Crusher integrated a key mechanical principle – the toggle linkage – a concept students of mechanics are familiar with In 1881, Philetus W Gates received a US patent for his device featuring the basic ideas of today’s gyratory crushers In 1883 Mr Blake challenged Mr Gates to crush 9 cubic yards of Types of Crushers: What You Need to Know Machinery

Cedarapids JW55 Jaw Crusher MPS

2024年8月22日 — MJ55 Designed around our proven, highperformance Cedarapids® JW55 jaw crusher, the MJ55 Modular Jaw Crusher is designed for large quarries or contractors that want a stationary type design without the complexity of2022年2月22日 — A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it Jaw Crusher: Range, Working Principle, Application 5 天之前 — The Senya 5 Portable Jaw Crusher has a 40kilowatt Yanmarpowered electric generator installed just under the feeder This single generator can power the MICRO crusher, conveyor and screen plant Boost efficiency further with the optional stepdown transformer upgrade option for onsite 220voltage and 110voltage powerPortable Jaw Crushing Plant Senya 3 Senya Crushers2023年2月28日 — A single toggle jaw crusher has one stationary jaw plate and one movable jaw plate A double toggle jaw crusher has two movable jaw plates that move back and forth to crush the material What is an overhead eccentric jaw crusher, and what are its advantages? An overhead eccentric jaw crusher has an eccentric shaft located above Primary Jaw Crusher – Everything You Need to Know

C5X Jaw Crusher Industrial Technology Group

2024年8月29日 — C5X Jaw Crusher The C5X Jaw Crusher features a welldesigned crushing chamber and outstanding motion characteristics, boasting a larger stroke and higher speed that enhance the crushing efficiency The entire machine offers improved reliability and is wellsuited for diverse working conditions It is capable of coarse and The right jaw design can make a big difference for your jaw crusher Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the application We have many case histories in which wear life increases of 50% are common, and some in which wear life increased up to 300%Jaw Crusher Wear Parts Columbia Steel Cast Products LLCUnrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applications Jump to content Crusher automation ACSc 5 ACSc 5 Stationary cone crushers 800iseries CS840i Nominal capacity 212 659 mtph (234 726 stph) Max feed size 431 mm (17 in)Rock Crushers, Stone Crushers, Screening and Crushing 2023年2月21日 — The hydraulic jaw crusher is ideal for crushing hard and abrasive materials, and it is commonly used in mining, metallurgy, building materials, and chemical industries One of the advantages of a hydraulic The Ultimate Guide to Jaw Crushing Machines:

.jpg)

How Does a Jaw Crusher Work Kemper

1 天前 — A fixed jaw, mounted in a Vshaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on the feed material by pushing it against the stationary plate The space at the ® C150™ jaw crusher is an effective jaw crusher in the 50ton (112 000 lbs) weight class It has been developed for the most demanding largescale mining and quarrying applications Crusher’s feed opening with long steep crushing cavity allows large coarse feed material up to onemeter (40”) size® C150™ jaw crusher 2022年12月22日 — JAW CRUSHER QJ341+ JAW CRUSHER KEY SPECIFICATIONS DATA Equipment Single toggle C12 jaw crusher Feed opening 120 m x 750 mm / 47” x 29” Maximum feed size 650 mm³ / 256 inch³ Engine CAT C93B Stage 5 / T4F 280 kW / 375 hp CAT C9 T3 261 kW / 350 hp CAT NR4 (China) 280kW / 375hp Transport dimensions TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW 2024年8月29日 — Finlay tracked Mobile Jaw Crushers are known for their capabilities in the reduction sizing of aggregates for construction recycling J1480 Finlay® J1480走行型可動式クラッシャーには、用途と材料によって最大750トン(826米トン)までの処理 Jaw Crushers Heavy Duty Finlay

C Series jaw crushers International Crusher

2018年1月17日 — group, has installed over 10 000 jaw crushers since the 1920s Today the C Series is indisputably the world’s favourite jaw crusher Where costefficient primary reduction of hard, abrasive materials is concerned, C Series crushers represent the highest technical and manufacturing knowledge All C Series jaw crushers are based on a3 天之前 — Compared with traditional jaw crusher, JC series jaw crushers pays more attention on details in the process of design and manufacture It uses highstrength materials, advanced manufacturing technology, which contributes to the stronger structure, higher reliability, larger crushing ratio, higher productivity, lower costJaw Crusher, Jaw Crusher price, jaw crusher manufacturer2024年8月29日 — Model: VYKIN 8JC Configuration: Jaw crusher Power System: Direct drive Engine: 14HP gas engine Fuel Consumption: 026 – 052 gal/hr, 158 gal capacity Electrical Control: Yes, wireless remote standard Hydraulic Control: Yes, tracks (rubber) Capacity: 28 TPH Crushing material: softertomedium hard rocks — such as concrete, limestone, VYKIN 8JC Mobile Mini Tracked Jaw Crusher VYKIN Crushers1 天前 — Jaw crushers are mainly used as primary crushers in mining, construction materials, infrastructure, and other sectors As the start of a highproductivity crushing line, using highquality replacement parts is Jaw Crusher Parts Aftermarket Wear and Spare

Jaw Crushers

2024年8月21日 — jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of applications Jaw crushers are typically used as primary crushers because they can Without considering the application and wider formula, manganese increases can result in weaker or less reliable crusher parts At Weir, we manufacture and supply a wide range of highquality crusher spare parts for our Trio® jaw and cone crushing equipment, as well as crusher wear parts and liners for a range of other crushing equipmentCrusher Wear Parts and Liners Weir Weir Group2023年2月15日 — The Dodge jaw crusher has a variable feed area and a fixed discharge area, which leads to choking of the crusher and is not ideal for hard materials Construction and Design: The Blake jaw crusher consists of a heavyduty frame that carries a fixed jaw and a movable jaw The movable jaw is pivoted at the top and is moved back and forth A Guide to Types of Jaw Crushers for Crushing Rocks and 6 天之前 — J1175 La trituradora de mandíbulas sobre orugas Finlay® J1175 es una trituradora móvil potente y de altas prestaciones Esta máquina incorpora un alimentador de criba de rejas vibratorio (Vibrating Grizzly Feeder, VGF) de velocidad variable para cargas pesadas que le otorga un rendimiento óptimo en aplicaciones para canteras, minería, Jaw Crushers Heavy Duty Finlay

.jpg)

Jaw Crushers Laarmann Group BV

LAARMANN Jaw crushers have set the industry standard for over 10 years so you can be assured the designs have stood the test of time They offer fast sample throughput with good reduction ratio and reduced sample contaminationChina leading mobile crusher manufacturer, specializing in produce crawler, jaw, impact and cone mobile crush, accounting for more than 70% of chinese market, feel free to contact us! Mesda is a professional manufacturer and supplier of mobile crusher and China Mobile Crusher Manufacturer MESDA GROUP2 天之前 — Liberty® Jaw Crusher Primary Maximum Feed Size 47″ (1,194mm) Maximum Reduction Ratio 6:1 Maximum Production Rate 1,595 STPH (1,446 MTPH) — Materials: Ore/Hard Rock, Quarried Stone, Recycled Asphalt, Recycled Concrete, River GravelCrushing Equipment Superior Industries US Manufacturer2019年12月10日 — The Dodge jaw crusher has a variable feed area and a fixed discharge area which leads to choking of the crusher and hence is used only for laboratory purposes and not for heavyduty operations The jaw crusher is usually made of cast steel because it is such a heavyduty machine Its outer frame is generally made of cast iron or steelType of crushers and their difference JXSC Mining

.jpg)

® C160™ jaw crusher

® C160™ jaw crusher is designed to be extremely reliable Its equipped to meet the expectations of customers who run their primary crushing plants 24 hours a day Based on customer experience and comprehensive testing, the critical areas of ® C160™ jaw crusher are protected against wearI bought a 10″ x 16″ jaw crusher from Mt Baker Mining in February 2014 for crushing concrete and demolition debris I have installed a 37 hp gasoline motor on the crusher so it is mobile and I can haul it on the back of my Jaw Crushers Mt Baker Mining and Metals2021年5月6日 — The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw The crusher discharge opening governs the size of Jaw Crusher Working Principle 911 MetallurgistCrushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be Jaw Crusher an overview ScienceDirect Topics

Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher

The powerful jaw crusher is capable of a variety of tasks with its large underbelt clearances, and is equipped with a hydraulic raise and lower facility on the main conveyor as standard There are a number of features to minimize operator intervention whilst maximizing their safety, such as the selflocking hopper and jaw level sensor which CRUNCHY COMPACT MiniJaw Crusher Crunchy compact Crunchy’s main features are the low noise level and the singlephase power supply with low electrical absorption (only 22 kW)Furthermore, the machine is sturdy, light and equipped with wheels so Crunchy Compact Jaws Mini Crushers2024年7月15日 — A jaw crusher can be sectionalized, therefore it is advantageous to install jaw crusher in remote locations, underground Jaw crusher machine installation cost is relatively higher than gyratory crusher while its investment and maintenance cost is much lower than that of gyratory crusher Jaw crusher and gyratory crusher process granite What Are the Differences Between The 7 Types of Crushers?Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is underjaw crusher 百度百科

.jpg)

Jaw Crusher Diagram: Simplified Guide JXSC

2024年2月18日 — A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals Comprising type of jaw crusher—the robust Singletoggle and the efficient Doubletoggle—these hefty machines operate on the principle of compressing materials between 2024年2月5日 — A jaw crusher operates by the movement of a movable jaw in relation to a fixed one to crush large rocks into smaller pieces It does this by using a spinning shaft that makes the movable jaw move back and forth When the movable jaw goes towards the fixed jaw, it squishes the stuff in between and breaks it into smaller bits How Does a Jaw Crusher Work? A Simple Guide JXSCThe core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse especially for jaw crushers In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that ® C Series™ jaw crushers